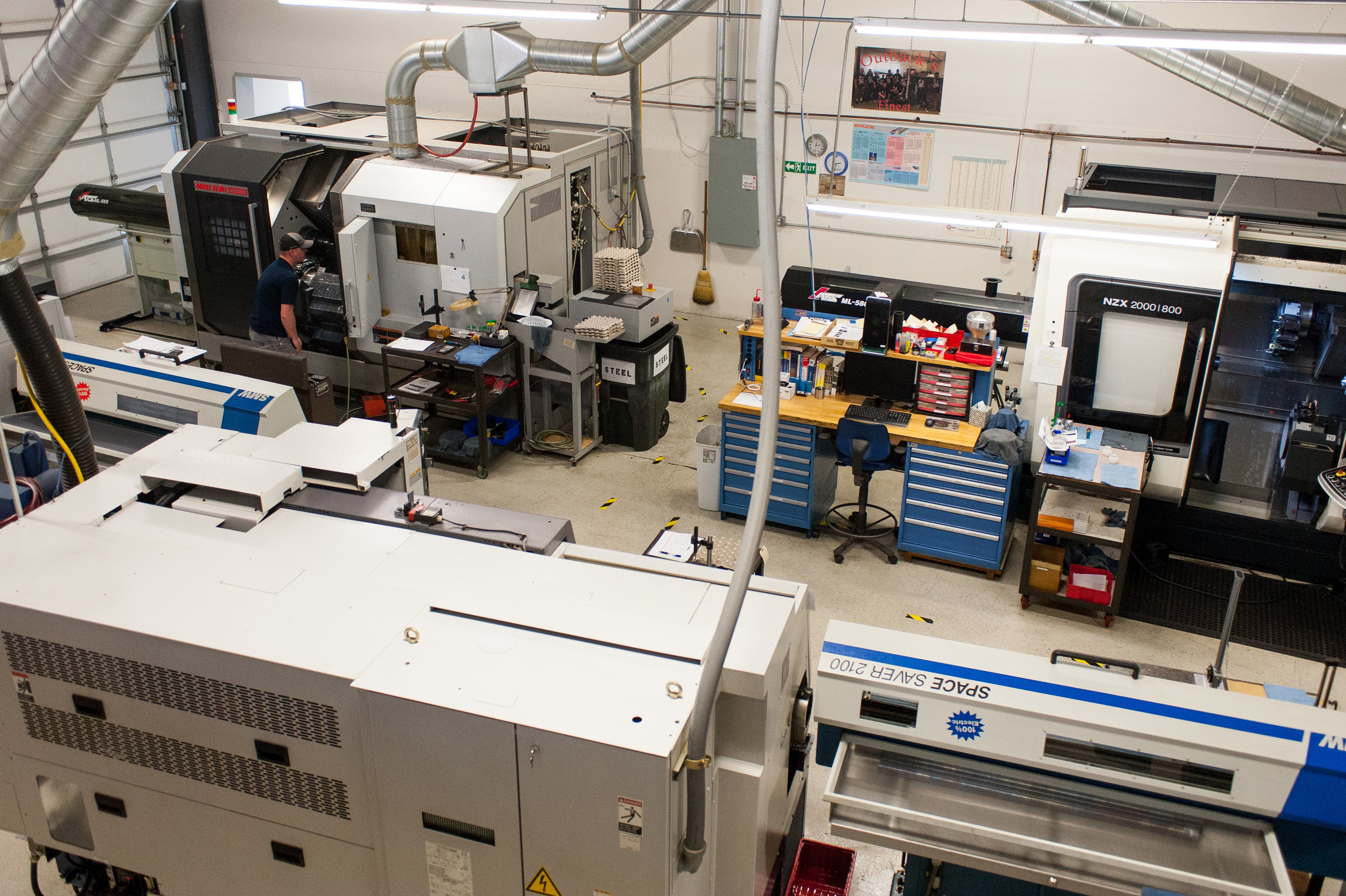

Overview

Outback Manufacturing has a state-of-the art, 20,000 square foot facility with the lastest CNC technology in a temperature controlled environment. We produce machine parts with tight tolerances, and complicated configurations. Our outstanding reputation throughout the industry makes us the ideal choice for your precision machining requirements. We work with aluminum, stainless steel, titanium, nickel alloys and plastics.

MAKINO a51 Machining Complex (MMC)

Our Makino a51 Cell System (MMC) features a fast spindle response that shortens machining times for parts and components. Made of light alloys with a cast iron base, the well-balanced support system enhances cutting capabilities in the uppermost region of the machining range. Rigid machine construction supports high acceleration performance.

Makino A51 MMC2 (x2)

(x) 22.0" (y) 22 (z) 23.6" 14,000 RPM High Power Spindle Rapid Travers

2360 in/min cutting feedrate

1,968 in/min maximum workpiece

24.8"x35.4" 360 degree Index Table

Maximum Payload: 880 lbs

ATC Capacity: 313

Tool to Tool: 0.9 seconds

Chip to Chip: 2.2 seconds

Maximum Tool Length: 18.1"

Maximum Tool Weight: 26.6 lbs

313 Tool Magazine

Tsugami SS327-II-5ax

1.25” diameter by 12.5” length

7-axis

36 tools

20 live tools

8000 rpm spindle (main and sub)

7000 rpm live tools

Mori Seiki NZ 2000

Triple Turret

12.6” Max Turning Diameter

31.9” Max Turning Length

Y-axis 3.9”

X-axis with live tools 12,000 rpm

48 tools

6,000 Spindle Speed

Mori Seiki NH5000 HMC

( X ) 24.5” x ( Y ) 23.5” x ( Z ) 26.4”

Full 4th axis

14000 rpm at 30hp

1000 psi thru spindle coolant

60 tools

High speed machining option

2 pallets available

Mori Seiki GV-503 VMC

( X ) 24.0” x ( Y ) 20.0” x ( Z ) 20.0”

12000 rpm

30 Tools

1000 psi thru spindle coolant

2 pallets available

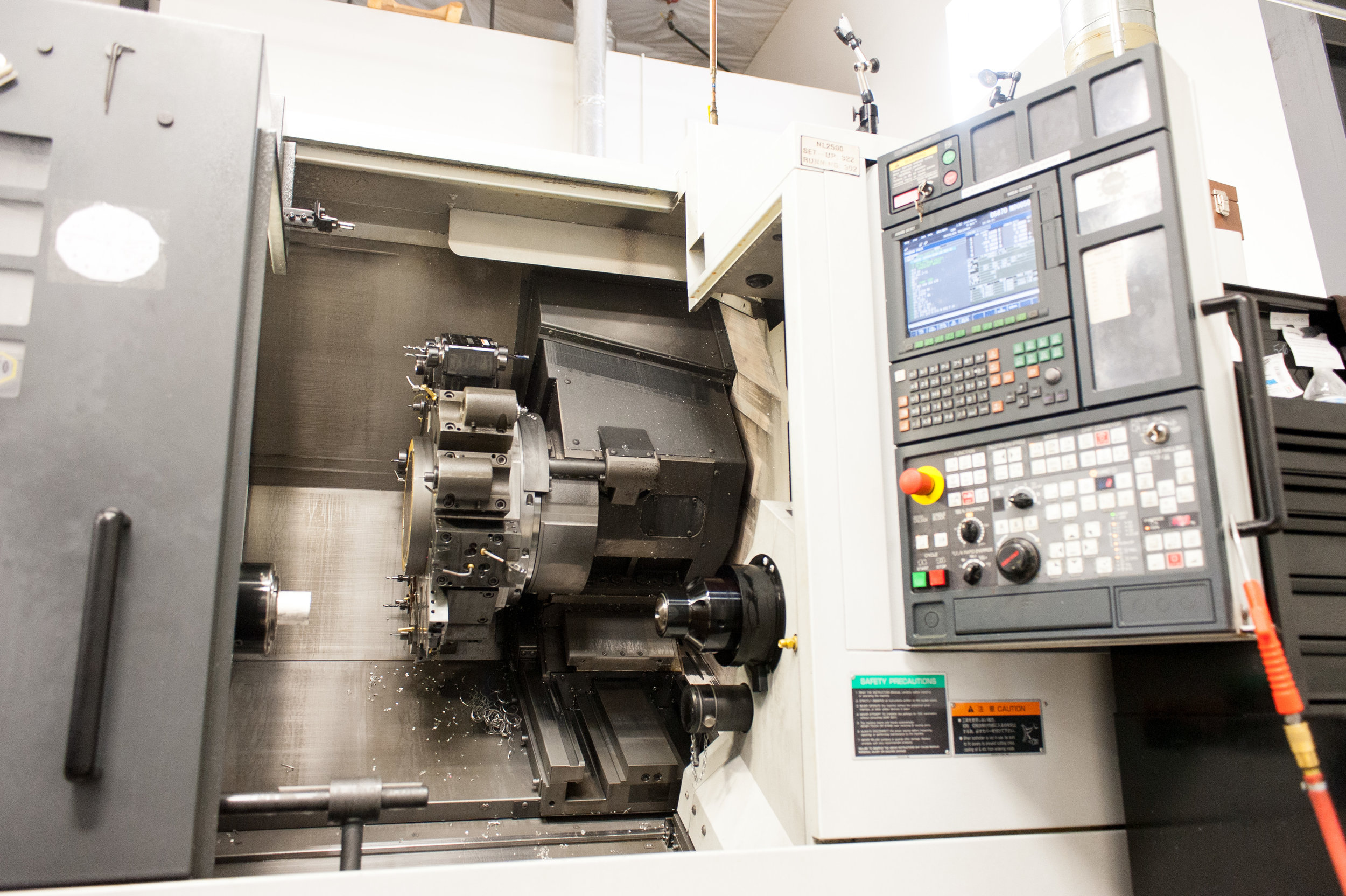

Mori Seiki NL2500SY/700

10” chuck Main 4000 rpm 3.1” thru

35 HP Main Spindle

6” sub spindle 6000 rpm

Y-axis 100mm

C-axis with live tools 6000 rpm

27.6 between spindles

Mori Seiki SL-250

10” chuck Main 3500 rpm 2.8” thru

6” sub spindle 3500 rpm

SMW bar feeder

C-axis with live tools 3000rpm

19.7” between spindles

Mori Seiki SL-253

10” chuck Main 3500 rpm 2.8” thru

6” sub spindle 3500 rpm

SMW bar feeder

C-axis with live tools 3000rpm

39.4” between spindles

Fadal 4020 (x2)

( X ) 40” x ( Y ) 20” x ( Z ) 28”

10000 rpm

21 tools

Hi torque spindle

Rigid Tapping

( 1 ) SMW indexer

Other Features of our Facility

KME 5 Axis Tombstone (x2) - Adds 5-axis capabilities to 4-axis machines

(Turning your volume down is recommended before playing the video)